The thickwall projector lense is made by rotational molding, which has a similar working principle as 2K/3K molding. Using our patented technology to reduce the cycle time.

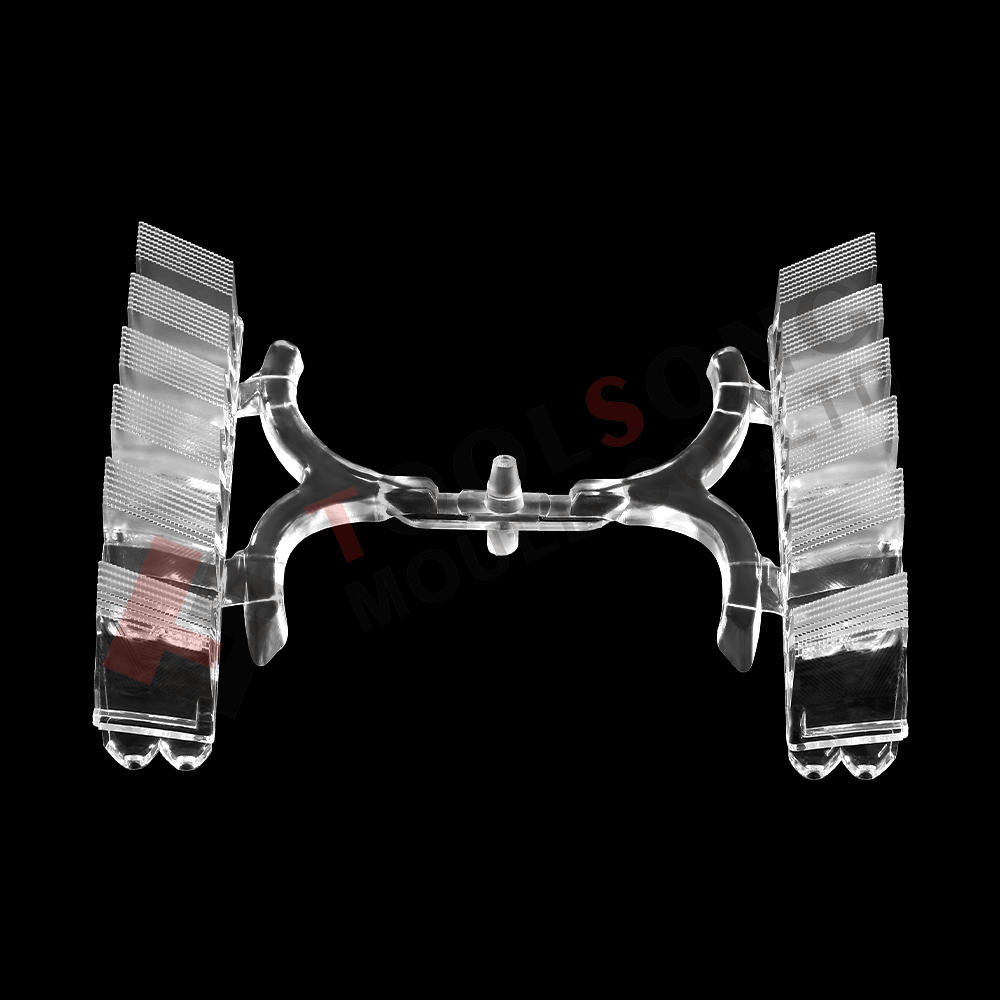

Plastic mould for bi-xenon projector lens with both high beam and low beam. Optics can be designed by our experienced optic engineer to meet different regulations.

Molds for optically clear lense, clear cut-off line, high-temperature resistant PC material. Mold steel Groditz 1.2343ESR/1.2344ESR, side gate.

Injection moulded fresnel lens with high light transmittance, high efficiency in focusing and high precision. Mold with two cavities, mold life 800,000 shots.

Transparent light guide with side gate. Considering the poor mobility of PC material, we make a moldflow simulation to check the pressure near the gates and adopt proper gates in mold design.

Knowing the importance of luminance, lit appearance, and optics to the optical part, we design the P/L and insert line away from the light source input face and output face.